New networking standards are offering Data Center Operators with higher speeds of today and tomorrow. Operators would need to support current and future computing requirements.

The trifecta of transmission speed, fiber-optic media and management capabilities will be one of the main consideration in building an essential foundation. Cost reduction and performance benefits will also drive the growth of 400G channels, which is expected to deploy a million transceivers by 2023.

We are certain to see more Fiber being deployed to satisfy the speed requirements where higher throughputs and bandwidths are going to continue.

In this webinar, we will address:

Who should attend?

The following is a transcript from the live Q&A session.

Q1. How can locking strap / buckle strap be used where ladder / rungs do not have serrated slots to insert the Strap?

Answer: Panduit offers various types of mounting brackets that can be attached to the ladder for proper installation even though the ladder rungs do not allow direct installation of Strap Cleats.

Q2. Do you have more information on mounting brackets?

Answer: You can find the information about mounting brackets from Panduit Cable Cleat Solution Guide. Kindly contact your local Panduit representatives for any assistance or email us at [email protected].

Q3. How can we position Locking Strap Cleats vs conventional Polymer Cable Cleats in terms of cost wise?

Answer: The price factor varies between manufacturers, depending on approval levels, quality and certifications. In most cases, Locking Strap Cleats are usually more competitive compared to conventional cable cleats. However, there is a need to also consider the labour cost, time needed, administrative, storage cost, etc. The total cost factors need to be considered.

Q4. I saw the installation comparison between Self Locking Cable Cleat and traditional Cable Cleat. What would be the installation time needed or time difference between Buckle Strap Cable Cleat and traditional Cable Cleat?

Answer: Installation of Buckle Strap Cleat requires just an additional step to fold back the buckle head to secure the installation. In general, Strap Cleats, regardless Locking or Buckle, are faster to install than traditional cleats.

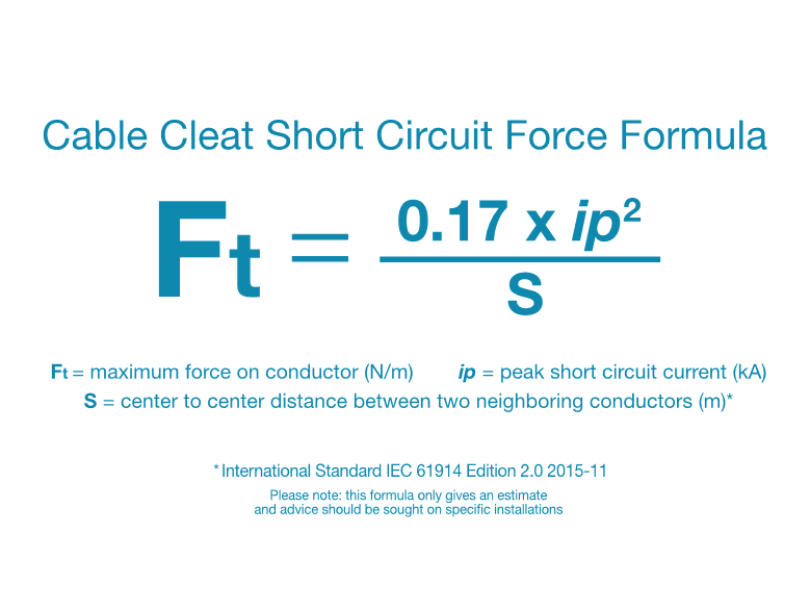

Q5. Does the formula also apply to quad formation?

Answer: Yes, the formula used for short circuit force calculation applies to both trefoil and quad configurations.

Q6. Do you have any testing videos of LV cables / Quadra 3-phase 4 wire?

Answer: Panduit had conducted actual short circuit testing on stainless steel quad cable cleat (CCSSQD series) in 3-phase 4 wire configuration. Kindly contact your local Panduit representatives for any assistance or email us at [email protected].

Q7. How many years can the plastic cable cleat last?

Answer: UV radiation and general weathering can have damaging effects on the long-term performance of plastic cable cleats. Panduit Non-metallic Cable Cleat is made of polymer material with UV stabilizer, which is designed for outdoor conditions. In compliance with IEC 61914 Standard, Panduit Polymer Cable Cleats are tested and certified to the required cleat testing parameters for use in intended application, including UV resistant. The outdoor durability is very subjective and dependent on many external factors. Without adverse outdoor conditions, we expect 15 - 20 years as a guide for Panduit Polymer Cable Cleats.

Q8. Is there a price competitive advantage over other companies?

Answer: Price factors vary between manufacturers, depending on approval levels, certifications and quality.

Q9. Are there any disadvantages of Strap Cable Cleat compared to traditional cable cleat?

Answer: Strap Cleats offer more advantages over traditional cable cleats, in terms of installation time, light-weight, low profile, greater range taking capacity, fewer SKUs and components to administer and manage. Once the Strap Cleat is installed, it is permanent and cannot be reused. For any modification, it needs to be cut off and re-installed with a new one. In most cases, cable cleats are secured at the final stage after everything is confirmed.

Q10. Why is it not applicable for Buildings?

Answer: Cable Cleats are applicable to buildings, whether they are industrial or commercial facilities. Cable Cleats are needed whenever there are power cables and anticipated short circuit fault risk.

Q11. Can you provide a link where we can download the product data?

Answer: You can download Panduit Cable Cleats Solution Guide for more information.

Q12. Does Panduit have Technical Guides for this Cable Cleat?

Answer: Panduit had published a white paper on the complete guide to cable cleat performance, testing, and design. It is an in-depth guide to the physics behind short circuit events - from how they affect electrical cable installations, to specifying and installing cable cleats that can withstand them. You may download the white paper for more information.

Q13. Is there any type of cable cleat that is easy to untie if we need any modification?

Answer: Traditional Cable Cleats that are installed with mechanical hardwares of bolts, nuts, washers, generally can be untied after they are installed. However, Strap Cleats is permanent and cannot be reused once it is installed. For any modifications, it needs to be cut off and re-installed with a new one. In field practice, regardless of traditional Cable Cleat or Strap Cleat, the installers will only do the permanent installation at the final stage after everything is confirmed.

Q14. What is the maximum size of cable can the cable cleats hold?

Answer: This varies between manufacturers. For Panduit, our Strap Cleats can support up to 177mm loop bundle diameter. This can be translated to 89mm outside diameter of single-core cable for trefoil configuration.

Q15. Any ready questionnaire which our sales reps can refer to have more clarity on which type of cleats to use?

Answer: There are various factors to consider, but most of the time, the customer would have an idea on the type of cable cleats they will need based on:

a. Application environment

b. Cable setup (ie: trefoil or single cable, etc)

c. Peak fault current ratings

Most importantly, we need to educate the customer or end-user on the risk of a short circuit fault event and the need for cable cleats.

Q16. Is it just High Voltage installations which require Cable Cleats?

Answer: All power cable installations should use cable cleats. Quite often the Low Voltage circuits have the highest Current and fault levels. The IEC Standard is written under Low Voltage Directives.

Q17. Why are there so many different types of cable cleat?

Answer: The type of cable cleat depends upon many factors, including fault levels, cable bundle configurations i.e.: trefoil, quad, single-cable, multicore cables, type of cable ladders/trays, and external environment, whether corrosive or non-corrosive.

Q18. What is the recommended spacing for a cleat along the cable runs?

Answer: There is no standard spacing. It all depends on cable configurations, cable diameter and peak kA fault level.

Q19. There are cable cleat suppliers with IEC 61914:2009, are they the same as IEC 61914:2015?

Answer: IEC 61914:2009 was the original standard. IEC 61914:2015 is the second version of the standard. 2009 version did not specify the range of cable diameters to be used in the short circuit test. However, the latest 2015 version standardizes the cable diameters range for testing. This is important as it removes ambiguity situations and provides an accurate representation of the cable cleats tensile capability.

Q20. With so many types of cable cleat, how do we know which type to introduce to customers?

Answer: There are various considering factors. Most of the time, the customers would have an idea which type of cable cleats they would need based on the:

a. Application environments

b. Cable diameter and type of cable setup (example: trefoil or single cable, etc)

c. Peak fault current level

d. Types of cable ladders

If they do not have a design preference, we will propose Strap Cleats.